How to Choose the Right Manufacturing Equipment for Your Business Needs

Choosing the right manufacturing equipment is a critical decision that can significantly impact the efficiency and productivity of your business. With a myriad of options available in the market, understanding the specific needs of your operations is essential for making an informed choice. The right manufacturing equipment not only enhances production capabilities but also aligns with the long-term goals of your business, ensuring that you remain competitive in an ever-evolving industry.

In this guide, we will explore the key factors to consider when selecting manufacturing equipment tailored to your business needs. From evaluating production volume and quality requirements to considering maintenance and support, each aspect plays a vital role in the decision-making process. Whether you are a startup looking to establish a footprint or an established entity seeking to upgrade your machinery, comprehending these factors will empower you to select the manufacturing equipment that best suits your operational demands. Through careful planning and strategic investment, your organization can achieve optimal performance, leading to sustained success in your manufacturing endeavors.

Understanding Your Business Requirements for Manufacturing Equipment

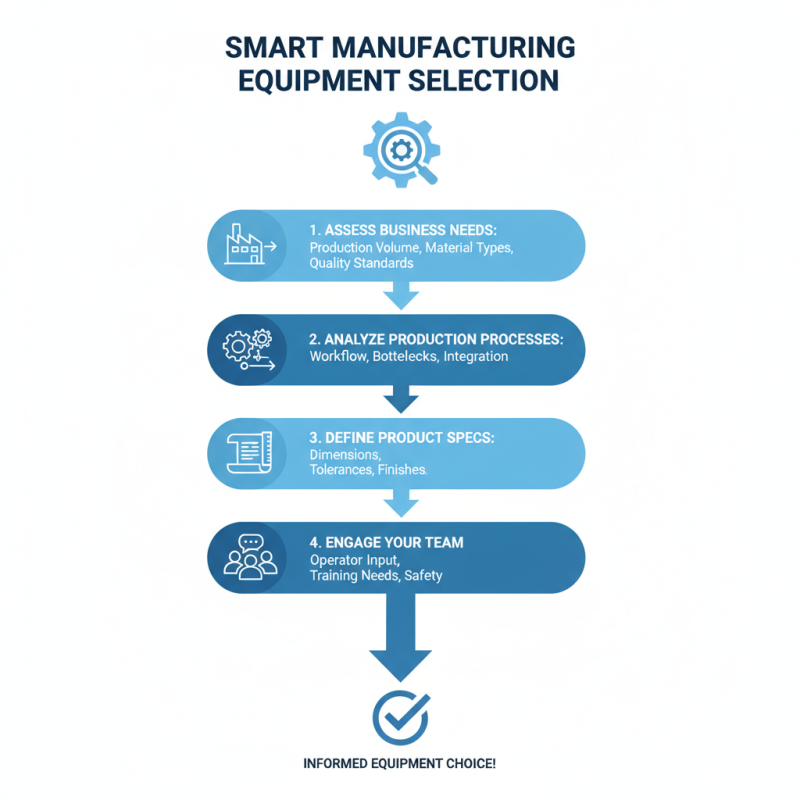

When selecting manufacturing equipment, it is essential to first understand the specific needs of your business. This involves a thorough analysis of your production processes, product specifications, and overall operational goals. Identifying the volume of production, the types of materials you will be working with, and the quality standards required will provide a clear framework for your equipment selection. Engaging with your team members who are directly involved in manufacturing can offer insights into everyday challenges and requirements, ensuring that the chosen equipment aligns with actual operational demands.

Additionally, consider the scalability of your manufacturing equipment. As your business grows, your equipment should be capable of adapting to increased production demands without compromising quality or efficiency. Taking into account potential technological advancements is also crucial; investing in equipment that can integrate with automation and digital solutions can enhance productivity and reduce operational costs. By clearly defining your business requirements and anticipating future needs, you can make informed decisions that not only meet your current demands but also facilitate long-term success.

Evaluating Different Types of Manufacturing Machinery Available

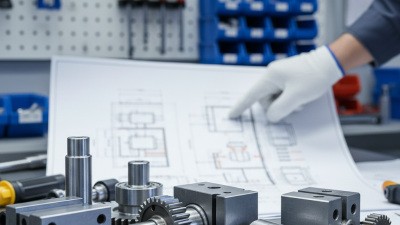

When evaluating different types of manufacturing machinery available, it is crucial to consider the specific processes that your business will utilize. Each type of machinery has its own unique capabilities and limitations, tailored for distinct manufacturing tasks. For instance, CNC machines offer precision and automation for metalworking, while injection molding machines are ideal for mass-producing plastic components. Understanding the nature of your production needs will help in selecting the most appropriate machine that aligns with your operational requirements.

Another essential factor to consider is the scalability of the manufacturing equipment. As your business grows, your production demands may change, requiring adjustments in machinery capabilities. Investing in flexible equipment that can adapt to varying volume requirements or product lines will save time and resources in the long run. Additionally, examining the maintenance and support associated with the machinery can influence your decision. Reliable equipment with accessible service options ensures minimal downtime and sustained productivity. In summary, a thorough evaluation of the machinery types, scalability options, and support services is fundamental in making an informed choice that aligns with your business objectives.

Assessing Budget Constraints and Total Cost of Ownership

When selecting manufacturing equipment, one of the most critical considerations is the budget constraints and the total cost of ownership (TCO). A lower upfront cost can be enticing, but it is essential to evaluate the long-term expenses associated with the equipment. This includes maintenance, energy consumption, and the potential for downtime. Investing in equipment with higher quality and efficiency may lead to reduced operational costs over time, making it a smarter financial choice despite the initial price.

Additionally, businesses must factor in the cost of training staff to operate the new machinery and any potential upgrades that may be necessary in the future. Evaluating TCO helps to create a more comprehensive picture of the financial commitment involved. By understanding all associated costs, companies can make informed decisions that align with their budgetary goals and operational requirements, ensuring that they select equipment that not only fits within their current financial constraints but also supports their long-term growth and efficiency objectives.

Exploring Industry-Specific Equipment and Technology Standards

When selecting manufacturing equipment tailored to your business requirements, it’s crucial to consider the specific standards that govern your industry. Different sectors possess unique technological benchmarks, which play a critical role in the functionality and effectiveness of the equipment. For instance, the food processing industry demands compliance with health and safety regulations, influencing the choice of machinery that not only meets production needs but also adheres to sanitation standards. Similarly, in the automotive realm, precision and automation standards dictate the type of equipment that can be utilized to optimize productivity and maintain quality.

**Tips:** Always conduct thorough research on the industry-specific regulations that apply to your business. Understanding these standards will help you select equipment that not only fulfills your immediate production goals but also aligns with compliance requirements.

Additionally, consider the scalability of the equipment. Industries often evolve, with technology advancements paving the way for improved processes. Choosing equipment that can be easily upgraded or expanded upon can save costs in the long run and position your business to adapt to future changes. This foresight ensures that your operations remain competitive and efficient as industry standards shift.

**Tips:** Engage with industry experts or communities to gather insights on emerging technologies that might influence future equipment needs. Networking can provide valuable information on best practices and new standards that could impact your equipment choices.

How to Choose the Right Manufacturing Equipment for Your Business Needs

| Equipment Type | Industry | Key Features | Technology Standards | Estimated Cost Range |

|---|---|---|---|---|

| CNC Machine | Manufacturing | Precision Cutting, Automation | ISO 9001, CE Mark | $30,000 - $300,000 |

| 3D Printer | Aerospace | Additive Manufacturing, Prototyping | AS9100, ASTM F2792 | $1,000 - $500,000 |

| Injection Molding Machine | Plastic Manufacturing | High Volume Production, Custom Parts | ISO 9001, UL Certification | $15,000 - $300,000 |

| Robotic Arm | Automotive | Versatile Automation, Precision Handling | ISO 10218, IEC 61508 | $20,000 - $150,000 |

| Laser Cutter | Metal Fabrication | High Precision Cutting, Speed | ISO 7010, CE Mark | $10,000 - $500,000 |

Analyzing Supplier Reputation and Support Services in Equipment Selection

When selecting manufacturing equipment, evaluating the supplier's reputation and their support services is vital for ensuring long-term success. Research shows that nearly 70% of manufacturers cite equipment reliability and supplier support as key factors in their purchasing decisions (Smith & Associates, 2022). A supplier with a strong reputation not only provides dependable machinery but also offers essential after-sales support, which can significantly reduce operational downtime. A recent industry report indicated that manufacturers who partnered with highly-rated suppliers experienced 25% fewer equipment failures and better overall productivity metrics, highlighting the importance of a solid supplier relationship.

Moreover, assessing the availability of technical support and maintenance services can enhance a company's operational efficiency. A study by the Manufacturing Institute in 2021 found that organizations benefiting from robust supplier support experienced up to a 40% increase in equipment lifecycle compared to those with limited supplier interaction. This emphasizes that when choosing manufacturing equipment, businesses should prioritize suppliers who offer comprehensive training programs, accessible technical assistance, and timely maintenance services. The right supplier not only provides quality equipment but also contributes to creating an agile manufacturing environment that can adapt to changing market demands.

Related Posts

-

2025 Top 5 Sanitary Pad Manufacturing Machines: Innovations Driving 10% Market Growth

-

How to Choose the Right Manufacturing Machine Parts for Optimal Efficiency

-

What is Diaper Manufacturing Techniques and Their Importance in the Industry

-

Why All Manufacturing Machines Are Essential for Modern Production Efficiency

-

Why You Should Invest in a Diaper Machine for Your Business Today

-

2025 Top 10 Manufacturing Industrial Machinery Innovations You Need to Know