Why You Should Invest in a Diaper Machine for Your Business Today

In today's competitive market, the increasing demand for disposable diapers presents a lucrative opportunity for businesses willing to embrace innovation. According to a report by Grand View Research, the global disposable diaper market is expected to reach USD 88.55 billion by 2025, growing at a CAGR of 5.4%. This growth underscores the potential profitability of investing in a diaper machine, which can not only enhance production efficiency but also allow for customization to meet specific consumer needs.

Industry expert Dr. Emily Roberts, a leading analyst at the Diaper Manufacturing Association, emphasizes the importance of this investment by stating, "A diaper machine allows businesses to scale operations while ensuring product quality, resulting in a better alignment with market demands and consumer expectations." By integrating advanced technology, businesses can streamline their manufacturing processes, reduce costs, and ultimately increase their market share in an ever-expanding industry.

Industry expert Dr. Emily Roberts, a leading analyst at the Diaper Manufacturing Association, emphasizes the importance of this investment by stating, "A diaper machine allows businesses to scale operations while ensuring product quality, resulting in a better alignment with market demands and consumer expectations." By integrating advanced technology, businesses can streamline their manufacturing processes, reduce costs, and ultimately increase their market share in an ever-expanding industry.

With the rising focus on sustainability, many companies are also exploring eco-friendly materials and production methods. This trend highlights the importance of being equipped with a cutting-edge diaper machine, allowing manufacturers to adapt swiftly to changing consumer preferences and regulatory requirements. As the market continues to evolve, investing in a diaper machine today could position your business at the forefront of the diaper manufacturing sector.

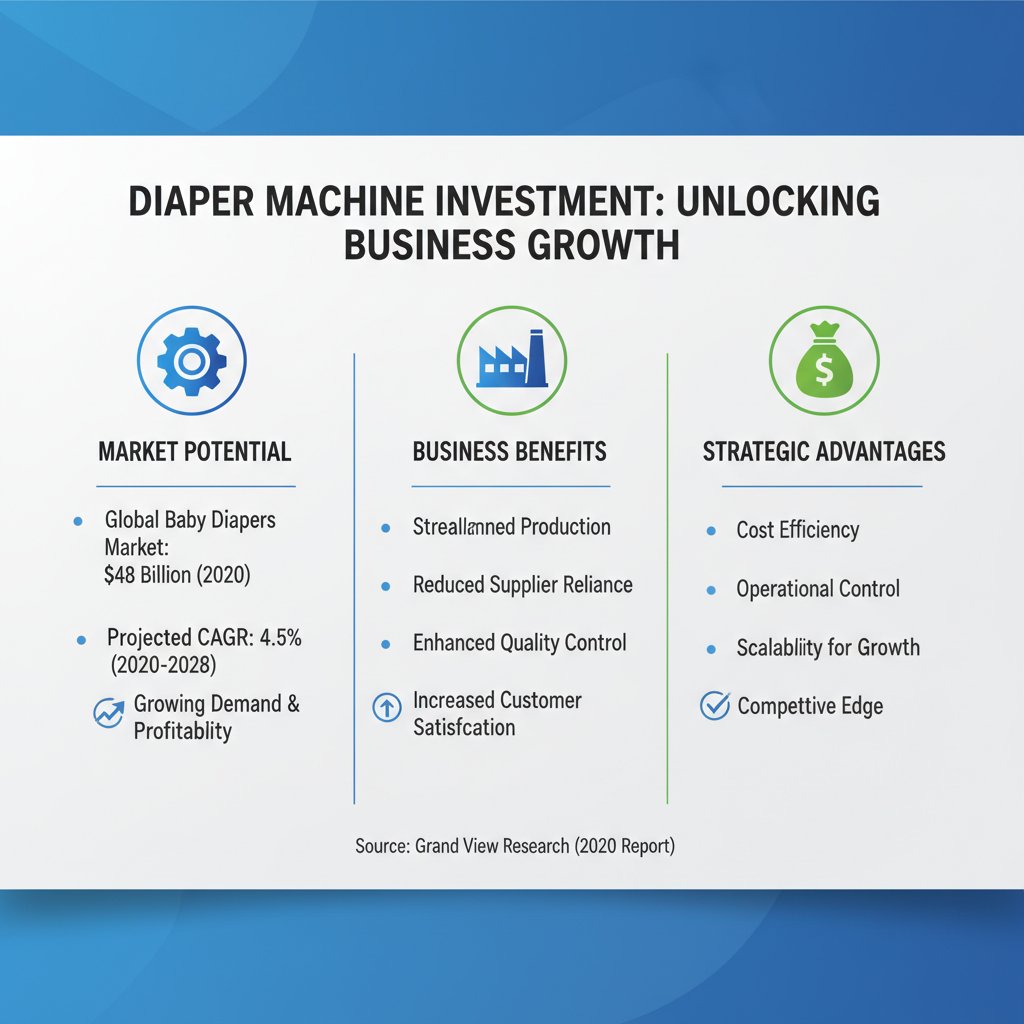

Benefits of Investing in a Diaper Machine for Business Growth

Investing in a diaper machine presents numerous benefits that can significantly contribute to business growth. According to a report by Grand View Research, the global baby diapers market was valued at approximately $48 billion in 2020, with expectations to expand at a compound annual growth rate (CAGR) of 4.5% through 2028. This surge in demand highlights the potential profitability for businesses in the diaper manufacturing sector. By utilizing a diaper machine, businesses can streamline production processes, reduce reliance on third-party suppliers, and gain greater control over product quality, ultimately enhancing customer satisfaction.

Furthermore, automation through diaper machines promotes efficiency, allowing companies to produce large volumes of diapers at reduced labor costs. A study from Research and Markets notes that technological advancements in manufacturing are anticipated to revolutionize production capabilities, potentially reducing manufacturing costs by as much as 20%. This cost efficiency enables businesses to either increase their margins or pass savings on to consumers, making their products more competitive in an ever-expanding market. The strategic investment in a diaper machine not only facilitates scaling operations but also positions businesses to adapt to market trends promptly, ensuring sustained growth and profitability.

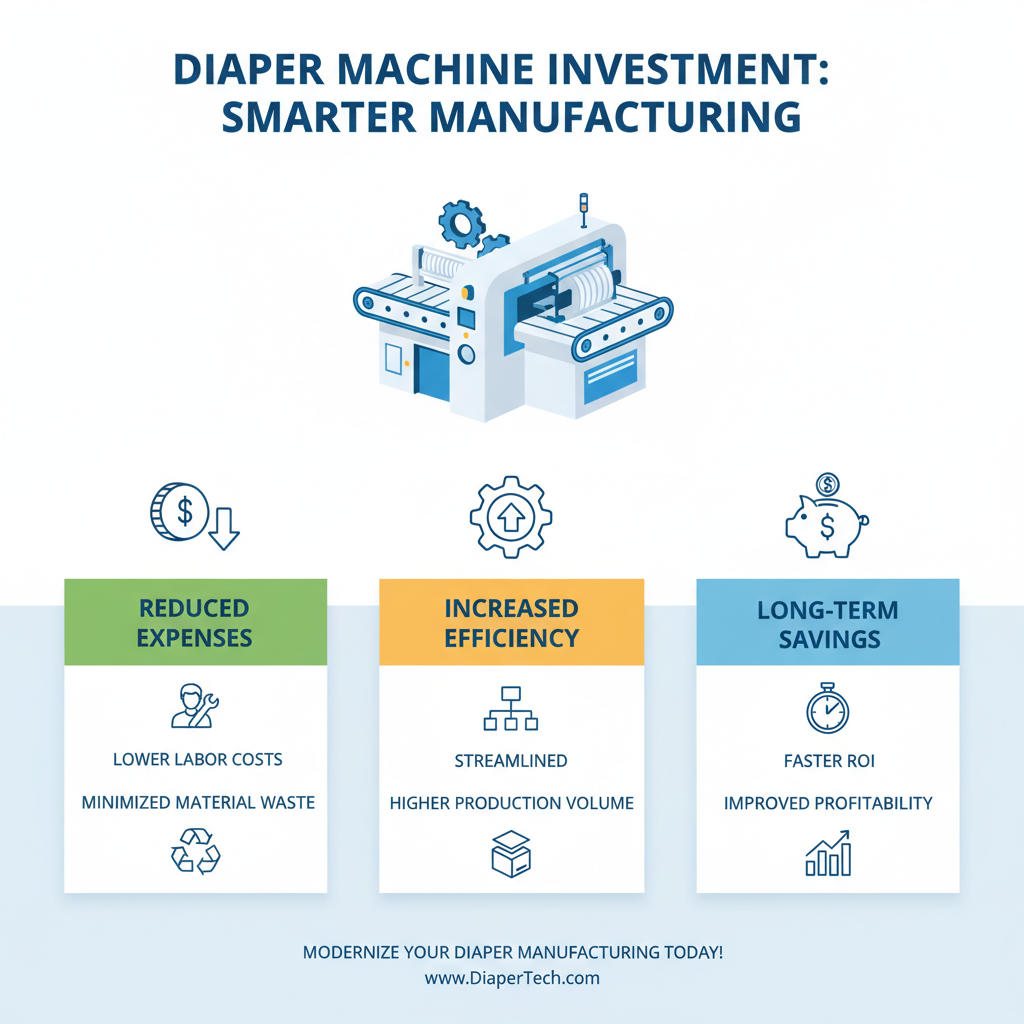

Cost-Effectiveness: Analyzing Production Expenses with Diaper Machines

Investing in a diaper machine can significantly reduce your production expenses, making it a wise choice for businesses in the diaper manufacturing industry. The initial investment in equipment may seem daunting, but the long-term savings are undeniable. By streamlining the production process, diaper machines minimize labor costs and increase efficiency, allowing your team to produce higher volumes in less time. Additionally, the precision of modern machines ensures that materials are used effectively, reducing waste and contributing to overall cost savings.

Tips: When considering a diaper machine, look into models that offer adjustable settings to accommodate different diaper sizes and styles. This flexibility can open new markets for your business, leading to increased sales. Also, consider the energy efficiency of the machine, as greener options not only help the environment but also lower your utility bills over time.

It's also crucial to perform a thorough analysis of your current production costs before making the investment. This will help you identify specific areas where savings can be achieved. Create a budget that takes into account maintenance and operational expenses, ensuring that you factor these into your overall expense planning. By taking a comprehensive approach, you can confidently invest in a diaper machine that meets your business needs while optimizing cost-effectiveness.

Quality Control: Ensuring High Standards in Diaper Manufacturing

Quality control in diaper manufacturing is crucial for ensuring that the final product meets high standards of safety and reliability. Investing in a diaper machine not only streamlines production but also enhances the ability to monitor and maintain quality throughout the manufacturing process. Modern machines are equipped with advanced technology that allows for real-time data collection and analysis, enabling manufacturers to identify potential issues before they escalate into larger problems. This proactive approach significantly reduces the risk of defective products reaching consumers.

Furthermore, implementing stringent quality control measures helps build trust with customers. Parents are particularly discerning when it comes to products for their babies, and knowing that a diaper brand prioritizes quality can influence purchasing decisions. By utilizing a state-of-the-art diaper machine that incorporates quality checks at multiple stages of production, businesses can ensure that each diaper meets safety regulations and performance expectations. This commitment to quality not only protects the health of infants but also enhances the brand’s reputation in a competitive market.

Market Demand: Understanding the Growing Need for Diaper Products

The global demand for baby care products is surging, with the market projected to reach approximately $239.81 billion by 2024. This rapid growth signals a lucrative opportunity for businesses, particularly in the diaper segment. By 2025, the industry is expected to expand further, reaching an astonishing $254.27 billion, and forecasting a climb to $419.43 billion by 2032. Such figures indicate an undeniable upward trend, making now the perfect time for entrepreneurs to consider investing in diaper machinery.

The diaper market itself is diversifying, with an emphasis on various materials such as cotton, bamboo, and hemp, catering to a broad range of consumers from infants to adults. Specifically, the cloth diaper sector is anticipated to swell from $2.91 billion in 2025 to $6.49 billion by 2032, boasting a robust compound annual growth rate of 12.15%. Additionally, the adult diaper market is on a growth trajectory, with expectations of increasing from $11.55 billion in 2018 to $29.83 billion by 2032. Given these trends, businesses that invest in diaper manufacturing are well-positioned to capitalize on the burgeoning market, meeting the rising demand for personalized and eco-friendly diaper products.

Market Demand for Diaper Products Over the Years

Sustainability: Eco-Friendly Practices in Diaper Production Machines

Investing in a diaper machine presents a unique opportunity to embrace sustainability in the production process. With growing environmental awareness, modern diaper production machines have been redesigned to minimize waste and enhance eco-friendly practices. These machines utilize advanced technologies that reduce raw material usage and energy consumption, significantly lowering the carbon footprint associated with diaper manufacturing. By opting for eco-friendly materials, such as biodegradable polymers, manufacturers can create products that are not only effective but also contribute positively to the environment.

Moreover, incorporating sustainable practices into diaper production promotes a circular economy. Many of today's diaper machines are equipped to handle recycled materials, enabling businesses to take part in waste reduction efforts. This shift not only responds to consumer demand for greener products but also positions companies as responsible leaders in an industry often criticized for its environmental impact. By investing in a diaper machine focused on sustainability, businesses can enhance their brand reputation, attract eco-conscious consumers, and contribute to a healthier planet for future generations.

Why You Should Invest in a Diaper Machine for Your Business Today - Sustainability: Eco-Friendly Practices in Diaper Production Machines

| Feature | Description | Benefits | Sustainability Impact |

|---|---|---|---|

| Energy Efficiency | Utilizes advanced technology to reduce energy consumption. | Lower operating costs and reduced carbon footprint. | Less reliance on fossil fuels, promoting renewable energy use. |

| Biodegradable Materials | Capable of producing diapers from biodegradable materials. | Attracts environmentally-conscious customers and enhances brand image. | Reduces landfill waste and promotes sustainable material usage. |

| Water Conservation | Low water usage technology during production. | Decreases water costs and minimizes environmental impact. | Preserves local water resources and supports water conservation efforts. |

| Recycling Capabilities | Can process waste diapers into raw materials for new products. | Provides an additional revenue stream and reduces waste costs. | Encourages circular economy practices in the diaper industry. |

| Automation | Incorporates automated systems for efficient production. | Increases production speed and reduces labor costs. | Minimizes resource wastage and enhances overall efficiency. |

Related Posts

-

2025 Top 10 Manufacturing Industrial Machinery Innovations You Need to Know

-

How to Choose the Right Manufacturing Machine Parts for Optimal Efficiency

-

Why All Manufacturing Machines Are Essential for Modern Production Efficiency

-

What is Diaper Manufacturing Techniques and Their Importance in the Industry

-

Top 10 Diaper Manufacturing Equipment You Need for Efficient Production

-

2025 Top 5 Sanitary Pad Manufacturing Machines: Innovations Driving 10% Market Growth