2025 Top Trends in Manufacturing Industrial Machinery You Need to Know

In the rapidly evolving landscape of manufacturing industrial machinery, staying ahead of the curve is crucial for businesses looking to maintain a competitive edge. As projected by the latest report from the International Federation of Robotics, the global market for industrial robots is expected to grow by 13% annually, reaching a market size of $35 billion by 2025. This growth, fueled by advances in automation and smart manufacturing technologies, underscores the transformative shifts taking place within the industry.

Industry expert Dr. Emily R. Johnson, a leading researcher in manufacturing technologies, emphasizes the importance of innovation in this sector: "The future of manufacturing industrial machinery relies heavily on integrating advanced technologies such as IoT, AI, and machine learning to enhance efficiency and productivity." As we look to 2025, several key trends are emerging that will shape the future of manufacturing, including the rise of sustainable practices, increased digitization, and the push towards customizability in machinery production.

Understanding these trends is essential for stakeholders across the manufacturing spectrum. By harnessing the insights provided in this comprehensive outline, professionals can better navigate the complexities of the industry and leverage new opportunities that arise in the coming years.

Emerging Technologies Revolutionizing Manufacturing in 2025

In 2025, the manufacturing industry is poised for significant transformation, largely driven by emerging technologies that are reshaping industrial machinery. According to a McKinsey report, nearly 50% of manufacturers are expected to adopt AI and machine learning to optimize production processes. This shift not only enhances operational efficiency but also contributes to better decision-making in real-time. Additionally, the integration of IoT devices enables predictive maintenance, reducing downtime and maintenance costs by up to 25%, as per a Gartner study.

The rise of advanced robotics is another key trend, likely to revolutionize the production line. A report from the International Federation of Robotics indicates that the global market for industrial robots is expected to grow by 15% annually, facilitating greater precision and flexibility in manufacturing operations. By automating repetitive tasks, these advancements will allow human workers to focus more on complex problem-solving and creative tasks, increasing overall productivity.

Tip: Manufacturers should invest in upskilling their workforce to adapt to these new technologies. Providing training in AI and robotics will not only help employees stay relevant but also enhance innovation within the organization. Embracing these emerging technologies early can create a competitive advantage and streamline operations for the future.

Sustainable Practices Impacting Industrial Machinery Trends

As the manufacturing sector continues to evolve, sustainable practices are becoming central to the development of industrial machinery trends. According to a report by the International Energy Agency (IEA), energy efficiency improvements in the manufacturing industry could lead to a reduction of global energy consumption by up to 30% by 2025. This push for sustainability is not only driven by regulatory pressures but also by the demand for more environmentally friendly production methods from both consumers and stakeholders.

In this context, advanced manufacturing technologies such as additive manufacturing and automation are paving the way for a more sustainable future. A study from McKinsey suggests that implementing such technologies can decrease material waste by up to 50%, significantly contributing to lowering the carbon footprint of manufacturing processes. As industries adopt circular economy principles, the focus has shifted towards designing machinery that utilizes recycled materials and promotes energy recovery, which is now seen as a critical factor in maintaining competitiveness and meeting sustainability goals. The integration of these practices will undoubtedly shape the future of industrial machinery, positioning sustainability at the forefront of innovation.

2025 Top Trends in Manufacturing Industrial Machinery You Need to Know - Sustainable Practices Impacting Industrial Machinery Trends

| Trend | Description | Impact on Machinery | Implementation Year |

|---|---|---|---|

| Energy Efficiency | Increased focus on reducing energy consumption through innovative designs and solutions. | Reduction in operational costs and lower carbon footprint. | 2025 |

| Recyclable Materials | Utilizing materials that are easier to recycle in machinery production. | Enhancement of sustainability and reduction of waste generated. | 2025 |

| Smart Manufacturing | Integration of IoT and AI for real-time monitoring and optimization. | Improved efficiency and predictive maintenance capabilities. | 2025 |

| Carbon Neutrality Goals | Aiming for net-zero emissions in manufacturing processes. | Promotes long-term sustainability through reduced emissions. | 2025 |

| Circular Economy Initiatives | Developing processes that promote reuse and recycling of products. | Minimizes resource consumption and supports environmental conservation. | 2025 |

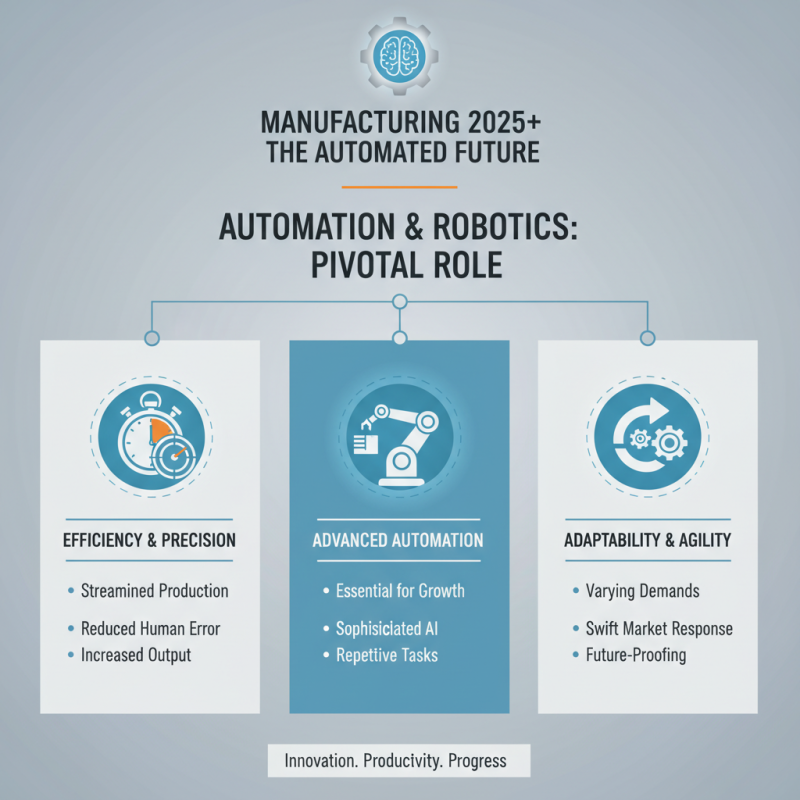

The Role of Automation and Robotics in Future Manufacturing

Automation and robotics are set to play a pivotal role in the manufacturing landscape of 2025 and beyond. As industries strive for efficiency and precision, the integration of advanced automation technologies will become essential. Automated systems can streamline production processes, reducing human error and increasing output. Robotics, equipped with sophisticated AI, will not only handle repetitive tasks but also adapt to varying production demands, providing manufacturers with the agility needed to respond to market shifts swiftly.

The rise of collaborative robots, or cobots, signifies a shift toward enhanced human-robot interaction. These systems are designed to work alongside human workers, enhancing productivity without compromising safety. By transferring mundane and physically demanding tasks to robots, human operators can focus on more complex and creative roles. This synergy will not only improve job satisfaction but also foster innovation, as employees will have the bandwidth to explore new ideas and solutions. As we look to the future of manufacturing, the seamless integration of automation and robotics will not only elevate operational efficiency but also redefine the role of the workforce in this evolving sector.

Key Market Players Shaping the 2025 Manufacturing Landscape

In 2025, the manufacturing industry is poised for unprecedented changes driven by key market players who are reshaping the landscape with innovative technologies and sustainable practices. Companies are increasingly adopting smart manufacturing techniques, leveraging artificial intelligence, and integrating automation to enhance productivity and reduce operational costs. This transformation is not just about optimizing processes; it's also about redefining business models to be more agile and responsive to market demands.

Tips for manufacturers looking to thrive in this evolving environment include embracing digital twins and IoT technologies to improve maintenance and efficiency. Engaging in partnerships with technology providers can also facilitate smoother transitions to Industry 4.0 practices. Moreover, investing in employee training is crucial, as the workforce must adapt to new tools and methodologies that promote versatility and continuous improvement.

Collaboration among key players is another significant trend to watch. By sharing resources and knowledge, companies can innovate more effectively and tackle common challenges, such as supply chain disruptions and sustainability goals. Encouraging an open environment for innovation, where ideas can flow freely, will be essential for staying competitive in a rapidly changing marketplace.

2025 Top Trends in Manufacturing Industrial Machinery

Predicted Challenges and Opportunities for Industrial Machinery

The industrial machinery sector is poised to face significant challenges in 2025, driven by rapid technological advancements and shifting market demands. One of the primary challenges will be adapting to Industry 4.0 principles, which emphasize automation, IoT integration, and data analytics. Manufacturers will need to invest in new technologies to stay competitive, often at high costs, requiring careful financial planning and resource allocation. Furthermore, there is the ongoing challenge of workforce skill gaps, as many existing workers may lack the necessary training to operate advanced machinery and systems, necessitating targeted education and training programs.

Conversely, these challenges also present unique opportunities for companies willing to innovate and evolve. The rise of smart factories can lead to increased efficiency and lower operational costs, offering manufacturers a chance to optimize their production processes. Additionally, as sustainability becomes a focal point in global manufacturing, companies can explore greener technologies and practices that not only comply with emerging regulations but also appeal to environmentally conscious consumers. By pivoting towards sustainable practices and embracing new technologies, industrial machinery manufacturers can enhance their market position and contribute positively to a more sustainable future.

Related Posts

-

Why All Manufacturing Machines Are Essential for Modern Production Efficiency

-

How to Choose the Right Manufacturing Equipment for Your Business Needs

-

Top 10 Diaper Manufacturing Equipment You Need for Efficient Production

-

2025 Top 10 Manufacturing Industrial Machinery Innovations You Need to Know

-

How to Choose the Right Manufacturing Machine Parts for Optimal Efficiency

-

2025 Top 5 Sanitary Pad Manufacturing Machines: Innovations Driving 10% Market Growth